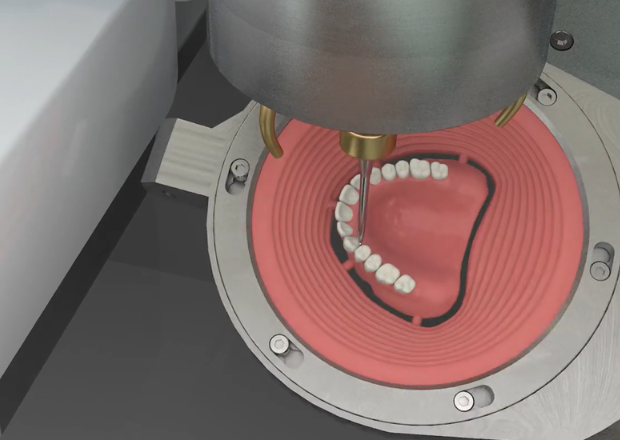

Scottsdale, Arizona-based AvaDent is an industry leader in the field of digitally designed and manufactured dental prosthetics, including monolithic digital dentures, overdentures and hybrid dentures, thanks to its innovative designs and processes. Established by Tim and Barbara Thompson, AvaDent delivers on Tim’s groundbreaking vision to automate denture design and manufacturing to achieve better-fitting dentures in less time. Thirteen years after its inception, AvaDent now holds over 80 patents as the company looks to cement its position as a leader by scaling manufacturing and management of its proprietary software.

Devon Howe, AvaDent’s general manager, had worked with a Manufacturing Extension Partnership (MEP) in New York in a previous position and knew about the organization's mission and focus. He contacted Arizona MEP to help the company tackle key initiatives and goals: scale manufacturing, ensure a safe work environment, strengthen IT protocols and provide leadership development opportunities to the next generation of leaders.

Reaching New Levels of Safety

AvaDent prioritized safety compliance and engaged Arizona MEP's safety expert to conduct a safety audit and help fix critical safety gaps. Together, they developed and implemented a structured safety program and manual and initiated regular safety meetings. The safety expert continues to conduct random OSHA mock inspections, ensuring continuous compliance with safety regulations and fostering a safety culture. As a result of these efforts, AvaDent has avoided fines and accidents but has also significantly improved its overall safety standards, demonstrating a firm commitment to the health and safety of its employees.

Lean Training and Optimization Leads to Significant Cost Savings

As an innovative start-up, AvaDent held a research and development mindset critical to innovation but not production. Arizona MEP was pivotal in transforming AvaDent's mindset and manufacturing efficiency through Lean training and a new floor layout. The training introduced basic Lean manufacturing concepts and helped the team identify inefficiencies and brainstorm how they could make improvements. The training sessions for floor supervisors were a crucial first step in AvaDent’s journey to improve the manufacturing process. Arizona MEP was then tasked with evaluating and providing alternatives to the facility's current layout. The factory’s new manufacturing configuration and adoption of Lean has increased gross margins from 40% to 50%.

Promoting Leadership Development

Wanting to foster growth and professional advancement, AvaDent enrolled mid-level employees in a comprehensive six-month leadership training program facilitated by Arizona MEP. The training focused on developing the skills new leads or supervisors need to be effective in their new roles. The training covers effective communication, time management, conflict resolution, change management and coaching for success. Building upon the positive feedback of the first group, AvaDent offered leadership training to the next tier of emerging leaders, ensuring a continuous pipeline of talent development within the company.

Enhanced IT and Digital Infrastructure Efficiency

AvaDent is always looking to enhance its IT and security infrastructure. “We're basically a software company that happens to make dentures,” said Howe. “We have a lot of smart people who've made some brilliant software. It's amazing.” While the company excels at software development, AvaDent recognizes the need to become more proficient at managing software revisions and accessing the data faster. Arizona MEP provided the company recommendations to trusted industry experts that can bolster software efficiency in AvaDent's computer-aided design processes and improve network security protocols. Despite the complexities of cybersecurity, AvaDent remains confident in selecting the right expert with Arizona MEP’s guidance and industry connections.

AvaDent Looks Towards the Future

Since beginning the relationship with Arizona MEP, AvaDent has made progress on its business goals, including developing a safety program and training, improving operations with Lean and new manufacturing layout, offering leadership training and more. AvaDent continues to work on improvements to its manufacturing process and relies on Arizona MEP to evaluate and provide input. “Arizona MEP has provided the expertise and support we need to scale our operations, and I know that I can go to them to receive advice that puts AvaDent’s interests first,” said Howe.